METALLURGICAL SERVICES

Our clients regularly contact the team at Materials & Testing Laboratories for advice and answers to metallurgy-related queries.

With a well-equipped mechanical laboratory and dedicated metallurgy laboratory, supported by an experienced team of in-house metallurgists, we provide expert support across a wide range of testing and analysis services. These include tensile strength testing, hardness testing, macro examinations, and impact testing. We specialise in failure analysis, helping clients identify the root cause of material or component failure using proven metallurgical techniques. Our broader expertise also covers materials selection, chemical analysis, microstructural examination, micro measurements, coating weight assessment, and more — all delivered with a strong focus on accuracy, insight, and industry best practice.

Contact us to discuss your metallurgical requirements — our expert team is here to provide you with clear, reliable, and comprehensive answers.

Chemical composition analysis

Chemical composition analysis is conducted for a wide range of purposes from material identification and characterization to quality control monitoring.

The analysis provides valuable information about the elements of a test sample. Chemical composition analysis or elemental analysis can be qualitative (determining what elements are present), and it can be quantitative (determining how much of each are present).

It is used to verify conformance to a standard or specification, to evaluate of raw materials, detect impurities or identify alloys. It is typically carried out using an Optical Emission Spectrometer that provides computerized processing and reporting results.

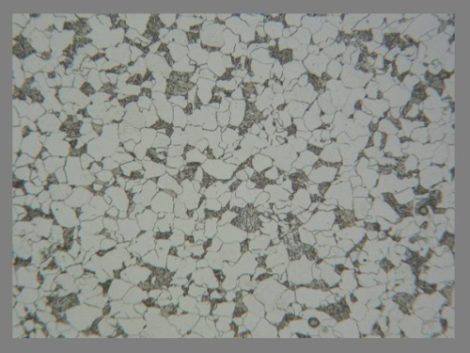

Microstructural analysis

Microstructural analysis testing is used widely to evaluate products and materials.

Metals have a preferred microstructure obtained by a specified processing or heat treatment to achieve desired material properties. A microstructural analysis can be performed to evaluate the microstructure in a metal alloy.

The observation is made at different magnifications depending on the observation to be made. The microstructure of a material allows to evaluate the state of supply and the possible presence of metallurgical defects.

Failure analysis

Failure analysis is a process by which a failed product is inspected to determine what caused it to fail. There are various methods that failure analysts use but all seek to determine the root cause of failure by looking at the characteristics and clues left behind.

It is useful to determine the root cause of failure. It’s beneficial to understand why a product failed. In the context of mechanical system failures, the failure analyst often uses visual inspection, microscopy, and various metallurgical tests (e.g. chemical analysis, hardness & tensile testing) to collect evidence.

It may allow to prevent similar product failures and improve future products.