Ensuring Rail Safety: Failure Analysis and Weld Integrity Testing in the Railway Industry

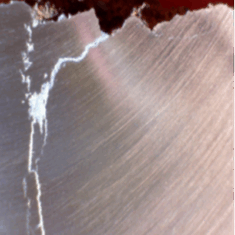

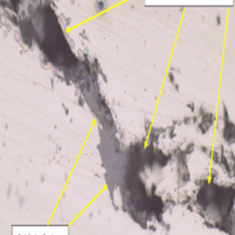

Our metallurgy team recently took on a project in the railway industry to address a critical issue: a failed rail sample that displayed cracking. This type of analysis is essential in transportation applications, where structural integrity and material durability are paramount to safety and long-term performance. Alongside failure analysis, we also conduct macro visual examination of flash butt welds on new rails to ensure each weld meets the high standards required for rail infrastructure.

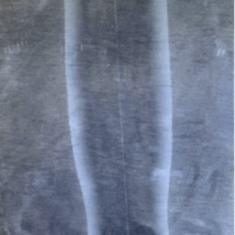

For this investigation, we used an optical microscope to conduct a detailed examination of the cracks, analysing the material’s microstructure to pinpoint the underlying causes such as micro cracks, cavities, non-metallic inclusions, micro pores and pores. Additionally, we performed micro-Vickers hardness testing to assess the hardness profile across the sample, which provided insights into material strength variations and potential weak points. These techniques allow us to offer reliable conclusions on failure causes, which are invaluable for preventative maintenance and quality assurance.

Our work on this project exemplifies the advanced methods and precision equipment we bring to the transportation sector. By consistently adhering to industry standards and best practices, we help our clients in rail infrastructure ensure that their materials meet stringent performance criteria. Projects like these highlight our commitment to supporting the safety and durability of essential railway systems, where every detail matters.