Failure Analysis of an Electric Motor Shaft in the Marine Industry

In this client case for New Zealand’s marine industry, our metallurgy team conducted a detailed failure analysis on an electric motor shaft from a hybrid-powered Greenline 40 yacht. This shaft, part of the hybrid drive system, operates under demanding conditions, switching between electric and diesel propulsion. With such cyclic stress, fatigue failure is a common challenge in components that must endure constant load and rotation in marine applications.

Our Approach to Fatigue Failure Analysis

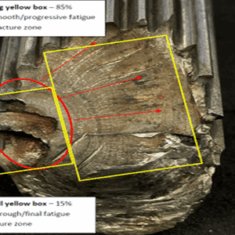

Our investigation involved a range of advanced techniques to pinpoint the failure mechanism. A stereoscopic examination provided an initial visual assessment of the shaft’s fracture surface, showing classic signs of fatigue failure. Fractographic analysis confirmed these findings, revealing ratchet marks, conchoidal marks, and radial patterns characteristic of torsional fatigue, with a 45-degree orientation to the shaft’s centreline. The fracture surface exhibited a blend of smooth and rough fatigue cracks (85% smooth and 15% rough), indicating a progressive failure mode.

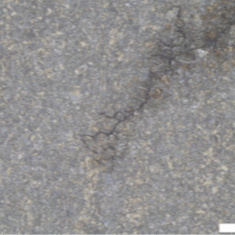

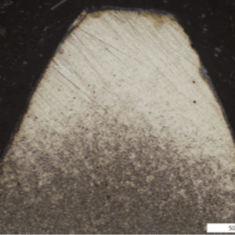

For further insight, we conducted a micro examination to study the microstructural features. The shaft’s cross-sectional microstructure revealed tempered martensite and secondary cracks at the root of the threaded area, with numerous micro-cracks near the fracture zone. These cracks displayed both intergranular and transgranular characteristics, typical of fatigue-induced damage in high-stress areas. A decarburisation layer was also observed on the threaded tip, likely contributing to the material’s fatigue susceptibility.

Additionally, a micro-Vickers hardness test allowed us to profile hardness variations along the shaft, supporting our findings of material consistency. Lastly, a chemical analysis confirmed the alloy composition, ruling out any deficiencies in material quality or manufacturing defects such as porosity or inclusions.

Supporting the Marine Industry with Reliable Analysis

This project underscores our expertise in fatigue failure analysis and highlights the crucial role of detailed testing in high-stress marine applications. By leveraging advanced techniques and global best practices, we help our clients in the marine industry and yacht manufacturing understand the factors contributing to equipment failure, enabling them to improve design and maintenance strategies. Through comprehensive diagnostics, we provide actionable insights that help our clients ensure durability and performance in critical marine components, supporting safer, more reliable operations in New Zealand’s demanding marine