Corrosion Analysis in Primary Industry Air Heater Using SEM and EDS

In a recent project for New Zealand’s primary industry, our metallurgy team addressed a corrosion issue observed on the internal surfaces of an air heater. Corrosion in such equipment can lead to inefficiency, downtime, and costly repairs—making prompt and accurate analysis essential. Our client reported yellow deposits and oxidation across various components, suspecting these issues were tied to flue gas condensation and material reactions within the heater.

The air heater in question was installed in a way that exposed its bottom surfaces to more condensation, due to frequent cold starts and low flue gas temperatures. As the natural gas combustion produces water vapour, mixing with traces of sulphur, this can create sulphuric acid in the presence of cooler temperatures. Our client also mentioned components constructed from diverse materials, including mild steel, magnetic stainless steel 22.12, stainless steel 316, and cast aluminium, each of which can react differently under corrosive conditions.

Our Approach to the Corrosion Analysis

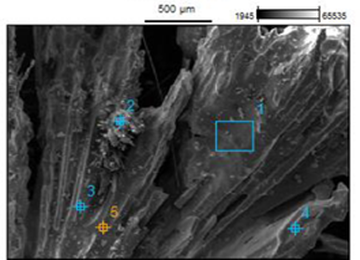

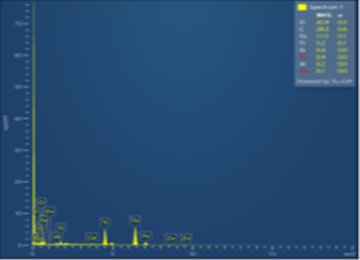

To accurately identify the corrosive particles and deposits, we used energy dispersive spectrometry (EDS) attached to a scanning electron microscope (SEM). This advanced method allows for a detailed chemical analysis of the sample’s surface composition, identifying elemental make-up and pinpointing potential contaminants or reaction by-products.

Our SEM-EDS results confirmed that sulphurous and sulphuric acids, formed from sulphur impurities in natural gas, reacted with condensation in the air heater. These acids contributed to the leaching of aluminium from the kaowool insulation (made from kaolin), leaving behind residual silica as a corrosive by-product. Additionally, the acids were found to corrode other materials, including zinc, aluminium, and steel, primarily during the burner’s downtime when condensation formed.

Delivering Insights for the Primary Industry

This analysis highlights our capability in corrosion analysis using SEM and EDS technology, enabling clients in the primary industry to diagnose and address issues related to material degradation. By providing a precise identification of corrosive elements and sources, we help our clients make informed decisions on maintenance and equipment installation practices to mitigate future risks.

Projects like this demonstrate our commitment to high-quality testing and failure analysis for New Zealand’s key industries, where reliability and durability are essential to operational success.