Salt Spray Corrosion: How Invisible Damage Starts and What to Do About It

There’s a calm kind of violence happening all around us.

You don’t hear it, you don’t see it at first—but it’s there, every day, carried in on the sea breeze. Salt spray. Tiny airborne crystals of sodium chloride, riding the wind and settling on everything from railings to industrial components.

And where salt settles, corrosion begins.

A Constant Environmental Pressure

New Zealand’s exposure to ocean air is near-universal. The wind brings salt far inland, and surfaces that seem untouched by the sea can accumulate enough chlorides to begin long-term degradation—especially when those surfaces stay damp or shaded.

What’s often overlooked is that coastal exposure isn’t limited to coastal views. Salt-laden air, particularly during storms and high winds, can deposit chloride particles dozens of kilometres inland, affecting infrastructure and components thought to be safe from marine influences.

How Salt Spray Travels and Attacks

Salt particles stay suspended in the air longer than most realise. Once deposited, they draw moisture from the atmosphere and trap it on metal surfaces. This moisture-chloride-metal combination sets up a textbook environment for corrosion, often on the microscopic level.

Even so-called corrosion-resistant materials like 304 stainless steel are affected. Once chlorides penetrate or disrupt the protective chromium oxide layer, pitting begins, often without visible signs until the material has already been weakened.

What Happens When Chloride Ions Reach the Surface – The Corrosion Mechanism

When salt-laden air deposits chloride ions onto a metal surface, especially stainless steels or coated carbon steels, it sets off a localized electrochemical process—a corrosion cell.

Here’s what happens:

- The passive film is breached

Most stainless steels (like 304 or 316) are protected by a thin chromium oxide layer. Chloride ions can break down this film at vulnerable points like inclusions, welds, or rough surfaces. - Anodic and cathodic sites form

Once exposed, metal atoms at the anodic site dissolve into ions. Electrons flow to the cathodic area, where oxygen and moisture complete the reaction. This closed-loop system feeds the corrosion. - Pits initiate and grow

Inside the pit, chlorides and metal ions lower the pH and increase acidity. This accelerates localised corrosion in a self-sustaining loop—the deeper the pit, the more aggressive it becomes. - Mechanical implications arise

Pits behave like notches or cracks, drastically reducing fatigue strength. Even a 1 mm deep pit in a stressed component can initiate failure under cyclic loads, particularly if it’s near a weld, edge, or load-bearing section.

Stress Corrosion Cracking (SCC): When the Material Fails Without Warning

SCC is a delayed, often catastrophic failure mechanism. It occurs when:

- Tensile stress is present (either from service loads or residual stress)

- The material is susceptible (common in austenitic stainless steels and high-strength alloys)

- A corrosive environment is active—typically chloride-rich, moist, and oxygenated

In this scenario, cracks form and propagate through the microstructure, often along grain boundaries (intergranular SCC) or directly across them (transgranular SCC).

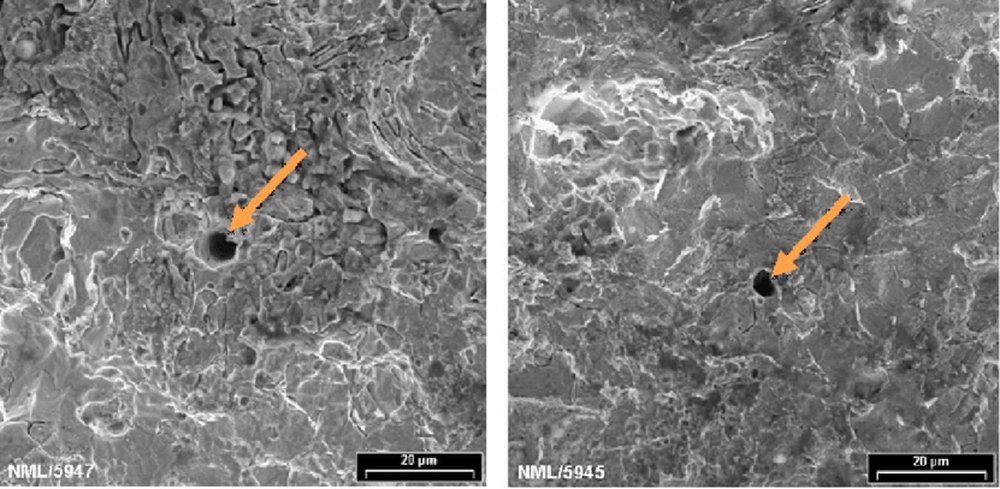

We’ve examined components that fractured cleanly under static load. SEM analysis revealed fine branching cracks, invisible to the eye but tracing back to pit sites and stress zones—often near welds or mechanically deformed areas.

What Corrosion Looks Like—And What It Doesn’t

Pitting corrosion is often invisible in early stages. A sample may appear clean and intact, even polished, while deep, narrow pits form just beneath the surface. These pits often concentrate near welds, bends, or poorly drained crevices.

Under magnification, the damage becomes clear: clusters of pits, microscopic corrosion networks, and signs of environmental attack that are easy to miss in a routine inspection.

How We Test for Salt-Related Corrosion

When corrosion is suspected—or when there’s exposure risk—we combine several techniques:

- Visual Inspection for surface clues

- Scanning Electron Microscopy (SEM) for pit and crack morphology

- Energy Dispersive Spectroscopy (EDS) to confirm chloride presence

- Salt Spray Testing (ISO 9227) to simulate accelerated corrosion

- Cross-sectioning and microhardness mapping for structural evaluation

These methods allow us to evaluate the severity and potential for future failure—even before visible rust or cracking occurs.

What Not to Rely On

❌ Visual checks alone—most corrosion begins below the surface

❌ The assumption that stainless means safe—304 can pit in months

❌ Good weather—salt deposits don’t always wash away with rain

❌ Design shortcuts—poor drainage or tight crevices trap salt and moisture

Designing Smarter for Salt-Exposed Environments

Where salt exposure is possible, long-term durability depends on proactive design:

- Use 316 or duplex stainless steels where chloride exposure is expected

- Eliminate sharp corners, crevices, and blind spots where moisture collects

- Promote drainage and air flow

- Consider coatings and surface treatments—but monitor and maintain them

- Understand residual stress—especially from welding or cold work

Material selection matters—but it only works when paired with sound engineering and inspection.

Seeing Failure Before It Happens

Our role isn’t just explaining why things failed—it’s preventing the next failure from happening.

By understanding early corrosion behaviour, recognising risk factors, and applying detailed analysis, we help engineers and operators make better long-term decisions about their components, materials, and maintenance cycles.

By the time corrosion is visible, it’s often late. With the right tools, we can see the signs long before the failure comes.

Not Sure What You’re Seeing? Start With a Sample.

Even if you’re just suspicious—discolouration, surface marks, unusual fatigue—send us a sample. We’ll tell you what’s happening underneath.